In the realm of machinery maintenance, precision is paramount. Achieving optimal performance requires meticulous attention to detail, and one critical aspect is shaft alignment. Laser alignment tools for shafts have become indispensable for this purpose, revolutionizing the way alignment tasks are approached. In this comprehensive guide, we will delve into the world of laser alignment tools, exploring their significance, types, best practices, advanced features, and emerging trends for efficient shaft alignment.

Understanding the Significance of Shaft Alignment

Misalignment of shafts is a prevalent problem in machinery, resulting in heightened wear and tear, diminished efficiency, and premature failure. Proper alignment ensures that shafts are positioned accurately, allowing for smooth operation and prolonged equipment lifespan. Laser alignment tools play a pivotal role in achieving and maintaining this precision, offering a reliable and efficient solution.

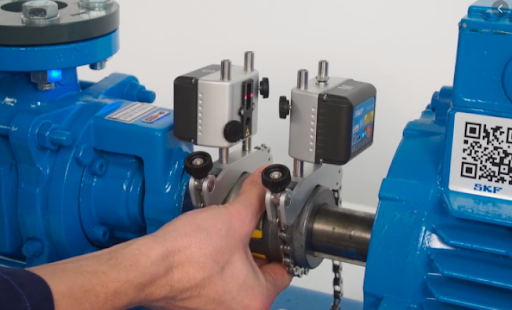

Types of Laser Alignment Tools

1. Single-Axis Laser Alignment Tools

These tools operate in a single plane, making them suitable for simple alignment tasks. They provide accurate measurements along one axis, facilitating quick adjustments to achieve alignment.

2. Dual-Axis Laser Alignment Tools

Dual-axis tools extend the functionality by measuring misalignment in two planes simultaneously. This comprehensive approach enhances accuracy, addressing both horizontal and vertical misalignments for more precise adjustments.

3. 3D Laser Alignment Tools

For complex machinery with three-dimensional alignment requirements, 3D laser alignment tools are indispensable. These tools offer a holistic view of misalignments in all three planes, allowing for comprehensive adjustments to ensure optimal shaft alignment.

Advantages of Laser Alignment Tools

- Precision: Laser alignment tools offer unparalleled precision, allowing for minute adjustments that significantly impact overall performance.

- Time Efficiency: Compared to traditional methods, laser alignment tools expedite the alignment process, reducing downtime and increasing operational efficiency.

- Cost Savings: The accuracy of laser alignment minimizes wear and tear, leading to extended equipment lifespan and reduced maintenance costs.

- User-Friendly: These tools are designed with user convenience in mind, featuring intuitive interfaces that simplify the alignment process.

- Versatility: Laser alignment tools cater to a wide range of machinery, adapting to various alignment requirements with ease.

Best Practices for Efficient Shaft Alignment

- Preparation: Before beginning the alignment process, ensure that the machinery is properly prepared. This includes checking for any loose components, ensuring the system is at ambient temperature, and securing the machinery in a stable position.

- Sensor Placement: Proper placement of the laser alignment sensors is crucial for accurate measurements. Follow the manufacturer’s guidelines for sensor positioning to achieve optimal results.

- Soft Foot Correction: Address any soft foot issues before proceeding with alignment. A soft foot can distort the machine frame, leading to inaccurate alignment measurements.

- Real-Time Adjustments: Utilize the real-time data provided by laser alignment tools to make immediate adjustments. This approach ensures that corrections are made promptly, reducing the likelihood of further misalignments.

- Documentation: Keep detailed records of alignment measurements and adjustments. This documentation serves as a valuable reference for future maintenance tasks and troubleshooting.

Advanced Features of Laser Alignment Tools

As technology continues to advance, laser alignment tools incorporate new features to further enhance their effectiveness. Some notable advanced features include wireless connectivity, automatic data logging, and integrated augmented reality interfaces. These features contribute to a more seamless and efficient alignment process, empowering maintenance professionals to achieve precision with greater ease.

1. Wireless Connectivity

Modern laser alignment tools often come equipped with wireless capabilities, allowing users to connect and control the device remotely. This feature streamlines the alignment process by eliminating the need for cumbersome cables and providing greater flexibility in positioning the equipment.

2. Automatic Data Logging

Advanced laser alignment tools simplify documentation by automatically logging alignment measurements. This not only saves time but also reduces the risk of manual errors in recording data. Automatic data logging ensures that comprehensive records are effortlessly maintained for future reference.

Emerging Trends in Laser Shaft Alignment

As industries evolve, so do the technologies associated with machinery maintenance. Laser shaft alignment is no exception, and staying informed about emerging trends is crucial for maintaining a competitive edge in the field. The merging of artificial intelligence (AI) and the creation of compact, portable laser alignment devices stand out as two significant trends.

1. Integration of Artificial Intelligence (AI)

AI is making significant strides in the field of maintenance, and laser alignment tools are increasingly incorporating AI capabilities. These smart tools can analyse alignment data in real time, identify patterns, and even predict potential issues before they escalate. The integration of AI adds a proactive dimension to shaft alignment, reducing the risk of unplanned downtime and enhancing overall equipment reliability.

2. Compact and Portable Laser Alignment Devices

The demand for flexibility and mobility in maintenance tasks has led to the development of compact and portable laser alignment devices. These lightweight tools, easily portable and ideal for on-the-go alignment tasks, prove practical for maintenance professionals in diverse settings across various industries due to their portability.

Conclusion

Laser alignment tools have undoubtedly transformed the landscape of shaft alignment in machinery maintenance. Their precision, efficiency, and versatility make them indispensable for achieving optimal performance and extending equipment lifespan. By understanding the different types of laser alignment tools, implementing best practices, and staying abreast of advanced features and emerging trends, maintenance professionals can navigate the evolving landscape of shaft alignment with confidence and proficiency.